Even though the most widely used processes in Polytech are injection moulding and extrusion, the research and development team also keeps

its attention on less widespread or evolving processes for large-scale productions.

These are currently the productive processes which we are testing and relying on:

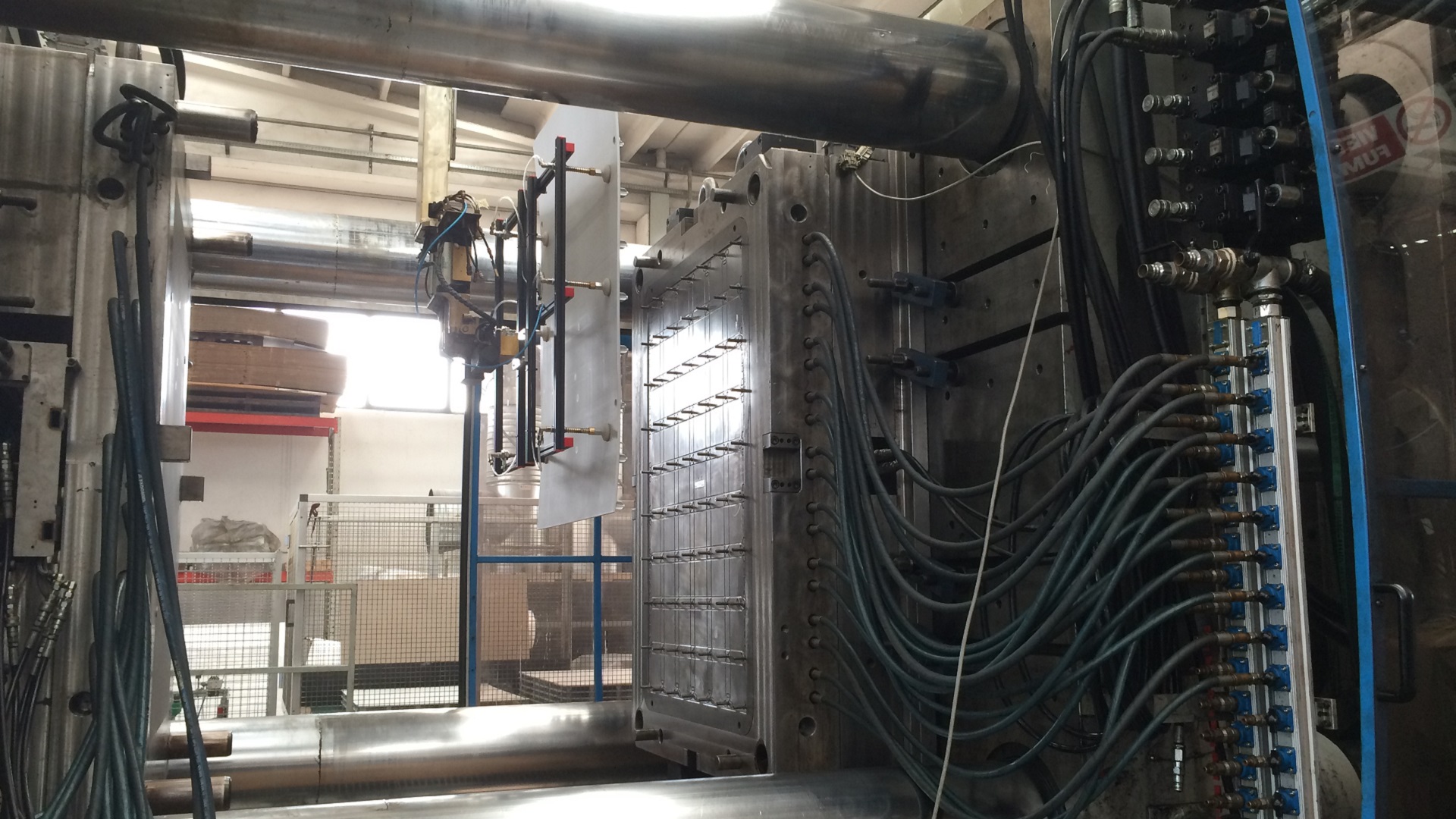

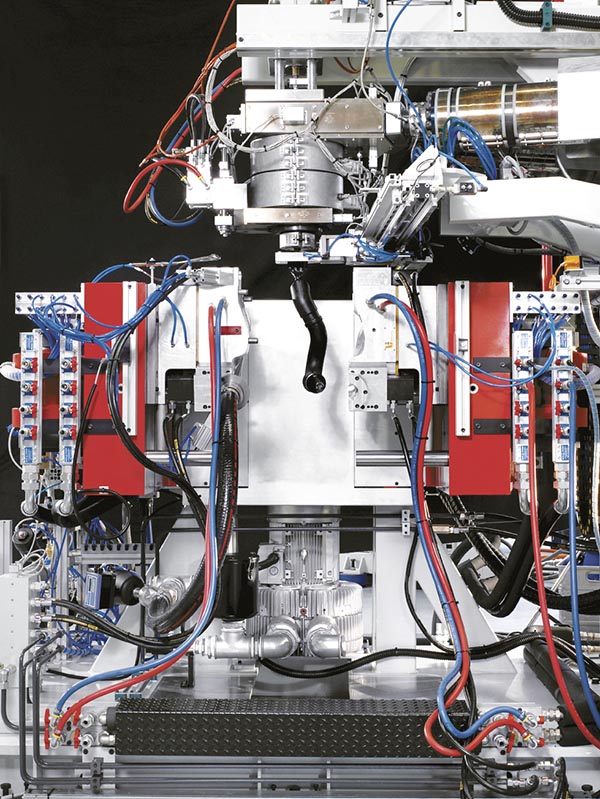

Is used to obtain products of large dimensions and in a wide range of weights, from a few grams to more than 20 kg. The press fleet of our

partners includes more than 100 machines, electric and hydraulic, with a closing force from 10 to 3500 tons, with injection capacity

from 14 g to 40 kg.

The extruders of our partners range from 25 to 150 kg / h capacity, single or double screw, both profile dies and flat heads, thus

obtaining the best polymer process dedicated to the specific profile geometry. In addition to polymeric materials, we also extrude aluminum

profiles which are designed by Polytech specifically to withstand high static loads. They are produced using aluminum alloys that combine

high mechanical resistance with lightness which facilitates transport and assembly on site.

The blow moulding process is one of the alternatives being studied by Polytech, intended for large hollow parts,

for which high rigidity and impact resistance are required.

The compression moulding process is also interesting for Polytech projects, for its versatility and the possibility of obtaining

components of high thickness with the use of tough polymeric materials.

The pultrusion process is well suited to the request of Polytech to obtain high-performance profiles of its own design thanks to the use of

continuous reinforcements (fibers, sheets, strips). Polytech works with partners to evaluate different combinations of polymeric reinforcements

and matrices, both thermosets and thermoplastics.

The lamination of thermoplastic polymeric materials is one of the processes that can be used to make panels with a sandwich structure,

high stiffness and low weight, which are highly requested in the construction sector.

On finished and semi-finished products we require processing for which our suppliers use different production technologies such

as forging, bending, laser cutting, punching, certified welding.